I. Overview

In recent years, the rapid development of China's communication industry has driven continuous innovation in microwave relay communication antennas. The transmission network function of satellite communication systems is mainly achieved through fiber optics, ground-based microwave, and air-based satellite communication methods. From the perspective of new technologies and transmission capacity used in microwave transmission systems, the next-generation synchronous digital hierarchy (SDH) microwave communication systems have gradually replaced traditional PDH microwave systems. To adapt to the frequency reuse technology in emerging SDH microwave communication systems, it is essential to develop ultra-high-performance microwave antennas. These antennas should feature a high front-to-back ratio (F/D), excellent cross-polarization discrimination (XPD), and a very low voltage standing wave ratio (VSWR). As a result, the ultra-high-performance microwave antenna system must achieve a VSWR better than 1.06 or a reflection loss greater than 30.7 dB, along with an XPD exceeding 38 dB.

II. System Composition

The feed system of the ultra-high-performance microwave antenna consists of several key components: a horn, an orthogonal device, a twisted waveguide, a curved waveguide, and a waveguide feed line. Among these, the horn and the orthogonal device are particularly critical for achieving optimal performance.

Horn

There are various types of horns suitable for feeding ultra-high-performance microwave antennas [1][2]. In this design, a planar corrugated horn with three chokes is used. This type of horn offers a rotationally symmetric radiation pattern, low side lobes, minimal cross-polarization, and a stable phase center. The structure of the horn is shown in Figure 1, consisting of a circular waveguide and three concentric rings. To improve the standing wave characteristics, a matching block is symmetrically placed near the horn’s aperture. Additionally, to prevent foreign objects from entering, the horn’s opening is typically covered with a dielectric film. However, such a film can degrade the standing wave performance. Using high-frequency simulation software, we optimized the position and thickness of the dielectric material to enhance the standing wave characteristics. The optimized horn achieves a VSWR better than 1.05.

Figure 1: Horn Structure

Orthogonal Device

In modern antenna feed systems, frequency reuse technology is one of the most cost-effective ways to utilize frequency resources, allowing for increased communication capacity. Orthogonal polarization frequency multiplexing uses dual-polarized antennas to transmit two independent signals on the same frequency by exploiting the orthogonality of polarization. There are two main techniques: two-line polarization and double-circle polarization [3]. The synthesis and separation of orthogonal polarizations occur within the feed system. Two-line polarization frequency multiplexing is typically implemented using an orthogonal mode coupler (OMT), also known as a polarization separator.

Orthogonal devices are commonly used microwave components, but there is limited literature describing their detailed design methods [4]. A normal quadrature (as shown in Figure 2) may appear to have only three physical ports, but it is electrically a four-port device. This is because the common port contains two orthogonal main modes (e.g., TE11/TE*11 in a circular waveguide or TE10/TE01 in a square waveguide), while the other two ports operate in their fundamental modes (e.g., TE10 in a rectangular waveguide or TEM in a coaxial line).

The function of the orthogonalizer is to separate the two independent signals carried by the orthogonal main modes at the common port and route them to the fundamental mode ports. This ensures that all electrical ports are matched and that there is high cross-polarization discrimination between the two signals. The ideal scattering matrix of the quadrature is represented as follows:

Figure 2: C-band Orthogonalizer

Ports 1 and 2 represent the two orthogonal main modes at the common port, while ports 3 and 4 correspond to the fundamental mode interfaces. The phase shift between them is φ1 and φ2, respectively.

Orthogonalizers come in various forms, each with slightly different performance characteristics. Commonly, they use circular or square waveguides, and in wideband applications, a four-ridge waveguide may be employed. The coupling hole in the branch waveguide (also known as the side arm) is usually located in the tapered region and is often short-circuited by a diaphragm or isolation barrier. The orthogonalizers described here meet the requirements of high performance and low cost within a narrow operating frequency band (10% to 20%). High performance demands low reflection loss (VSWR) and high isolation (port and polarization isolation), while low cost requires a simple structure and ease of fabrication.

To ensure the performance of the orthogonal device, its minimum operating frequency should be greater than 1.1 times the cutoff frequency (fmin > 1.1fc). This limits the maximum operating bandwidth of a circular waveguide orthogonalizer to approximately 17%, and that of a square waveguide orthogonalizer to about 25%. Within this bandwidth, the isolation performance is primarily affected by structural size and symmetry. If the operating frequency exceeds the maximum limit, higher-order modes can degrade the isolation performance.

The design of the orthogonalizer focuses on suppressing higher-order modes, simplifying the structure, ensuring symmetry, and achieving port matching with minimal components. The key to the design lies in the structure of the square or circular waveguide branch coupler and the matching of the two fundamental mode ports. The orthogonalizer we designed is shown in Figure 2. During the entire design process, the size of the square waveguide is first determined, followed by the design of the rectangular waveguide step transition for the through port. Finally, the position of the side arm coupling hole is established. It is crucial to select the size and position of the coupling hole to minimize interference with the straight arm and to ensure efficient polarization signal coupling. Due to the numerous variables involved in the side arm coupling structure, its performance plays a vital role in the overall system.

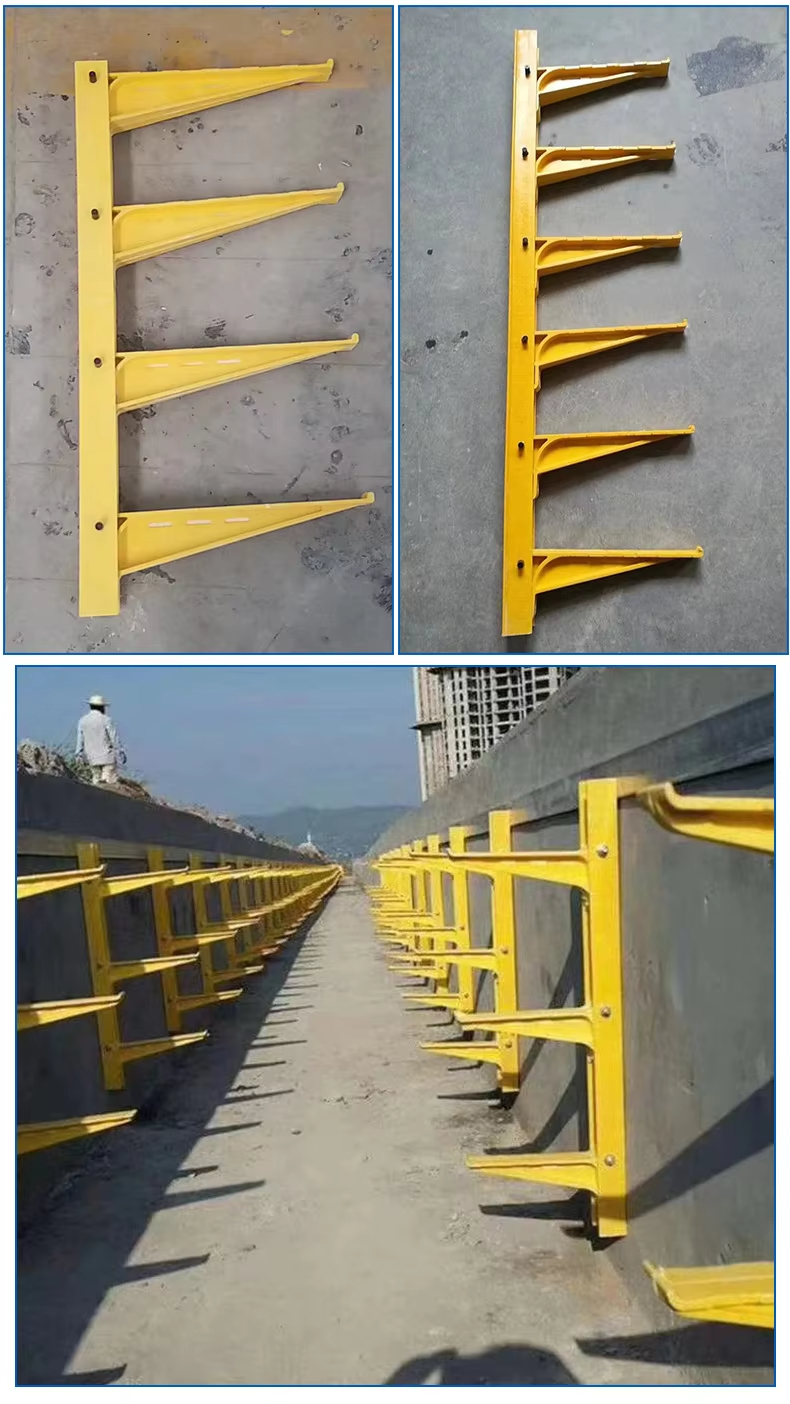

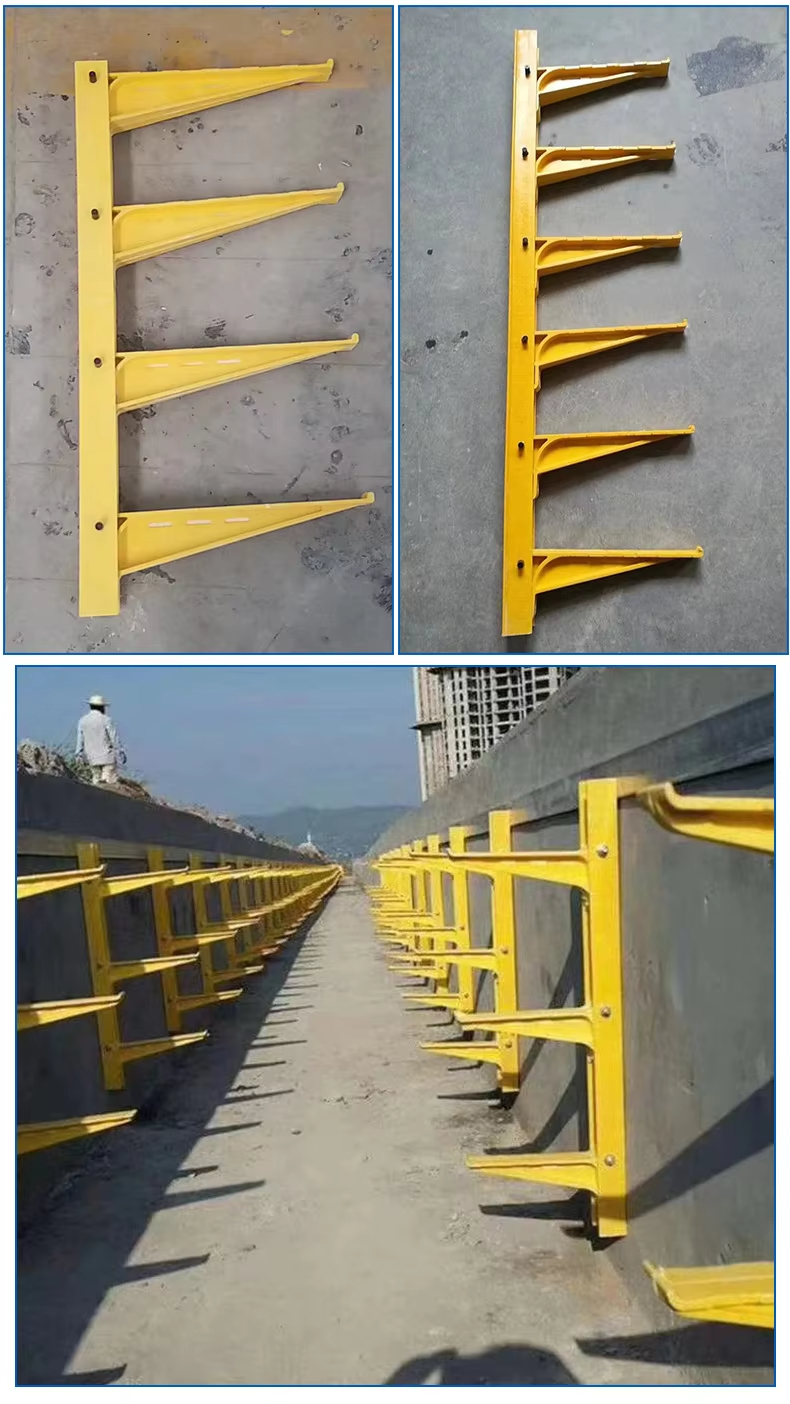

Fiberglass cable bracket is a steel frame made of composite material with synthetic resin as the adhesive and glass fiber and its products as the reinforcement material. It has good tensile and bending strength and is suitable for various cable section cable laying occasions. It is used for fixing the support of cables in power cable trenches and telecommunications cable trenches.

FRP Cable Bracket,Fiberglass Cable Trays,fiberglass cable tray,frp cable tray bracket

Hebei Dingshengda Composite Material Co., Ltd. , https://www.frpdsd.com